Case Study: Boiler Feed Pumps - JetTech Mechanical

Thank you to our friends at JetTech Mechanical for providing this case study

Use this link to download the printer-friendly pdf version: Case Study: Boiler Feed Pump

Introduction

JetTech Mechanical conducted routine vibration analysis on three boiler feed pumps at SRP Agua Fria Generating Station, a natural gas facility in Glendale, Arizona.

Each pump train includes a 3600 RPMEM synchronous motor, an American Blower / 'Gyrol' hydraulic variable-speed fluid drive, and a Pacific BB5 multistage pump. The sequence is:

motor → fluid drive → pump

with dynamics influenced by the flexible coupling and hydraulic internals. Units 1 and 2 started operation on February 7, 1958; Unit 3 began in 1961.

Hardware

AC192-1D

Compact accelerometer, 100 mV/g, ±10% sensitivity tolerance

MH114-3A

Multipurpose mounting magnet, 50 lbs. pull strength

CB103-K2C-010-F-SF

CB103 two-conductor cable with K2C two-socket MIL-style connector on the left, F BNC molded plug connector on right, and SF breakaway safety feature; 10 ft. length

BETAVIB VibWorks King

Data collector

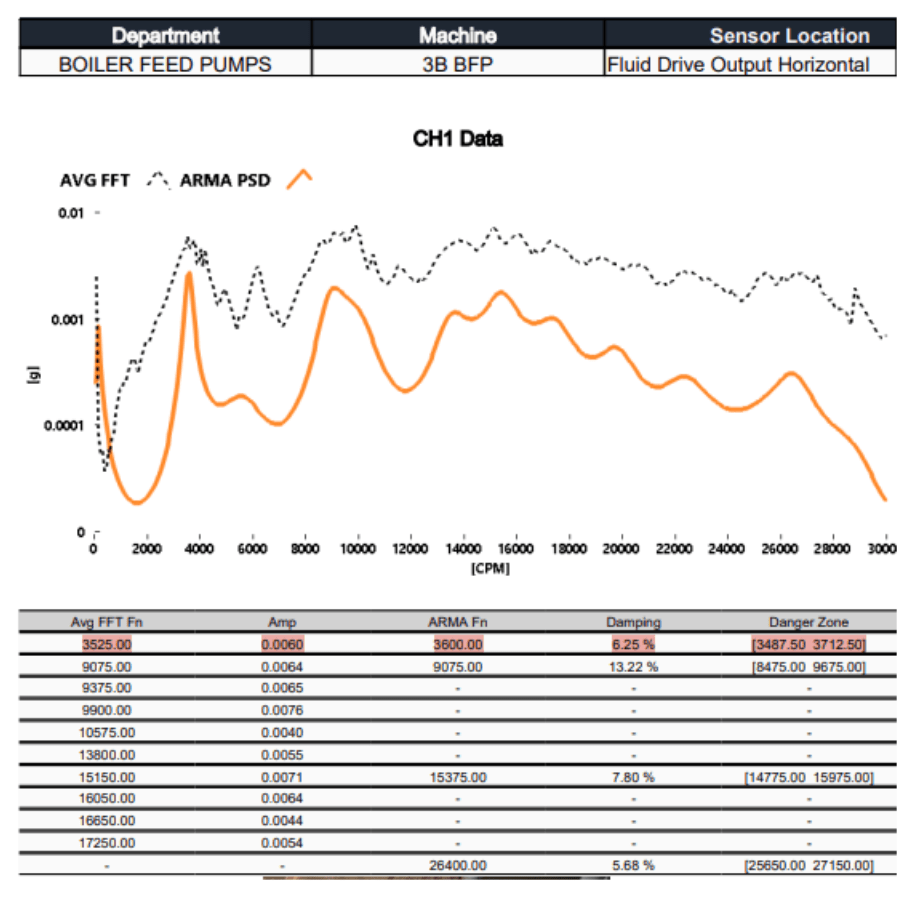

Observed Vibration Phenomenon

Vibration monitoring revealed that the fluid drive's natural frequency resonance in the horizontal direction lies between 3487 and 3712 RPM. With the motor operating at a constant 3600 RPM, within critical range, resonant amplification occurs horizontally, with a damping ratio of 6.25%. The danger zone is defined as 3487-3712 RPM.

Vibration Analysis

The resonance corresponds to a lateral natural frequency of the fluid drive rotor-bearing system. When the excitation frequency coincides with this natural frequency, vibration amplitudes rise significantly. The damping factor of 6.25% indicates limited energy dissipation, leading to pronounced resonance. The motor's synchronous rotation produces a constant forcing frequency of ~60 Hz (3600 RPM).

Impact Test Methodology

Impact testing was conducted using an instrumented hammer and accelerometers to stimulate and record the natural frequencies of train components. The assessment included the following test points: Fluid Drive Output Shaft (Horizontal & Vertical), Boiler Feed Pump Casing (Horizontal & Vertical), and Motor Non-Drive End (Horizontal & Vertical). All tests were performed while the unit was offline to guarantee consistent results.

Impact Test Results

Fluid Drive Output Shaft

Horizontal resonance was identified within the 3487-3721 RPM range, confirming the horizontal critical speed region. The vertical response exhibited lower amplitude and did not demonstrate significant resonance.

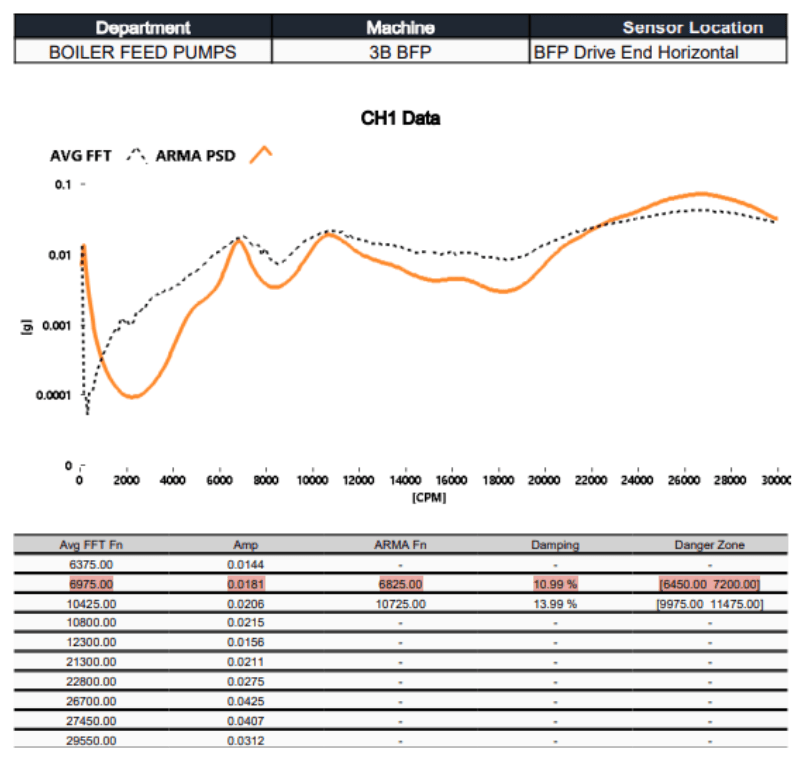

Boiler Feed Pump

The horizontal direction displayed some amplification near the fluid drive resonance; the vertical direction showed no notable resonance.

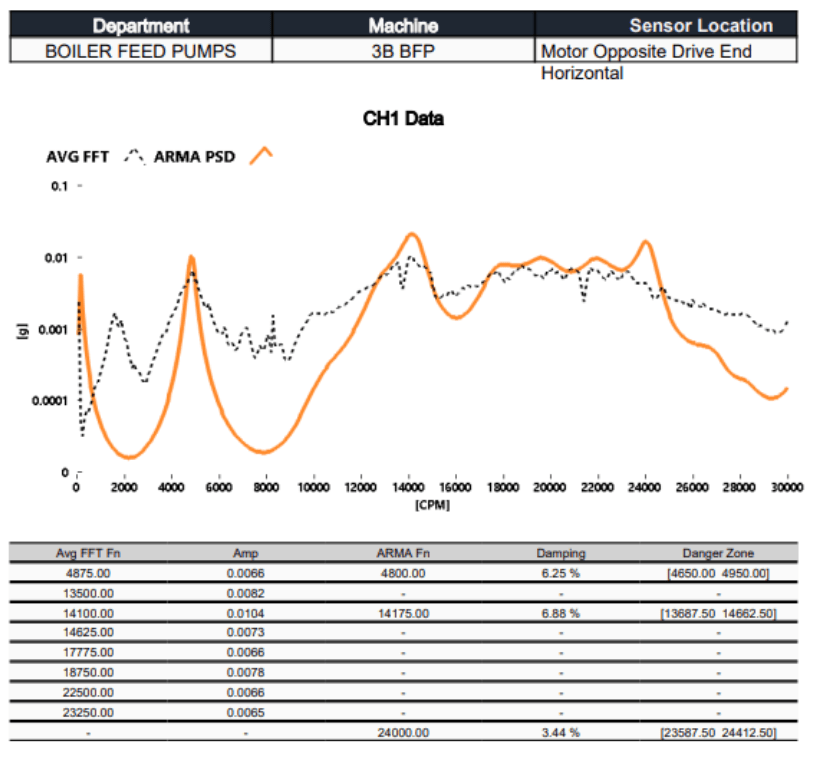

Motor Non-Drive End

Moderate horizontal response was recorded, but no dominant resonance was present. The vertical response remained stable with minimal amplification.

Operational Impact

Because 3600 RPM falls within the danger zone, the system constantly excites resonance during operation. This can lead to higher vibration, faster bearing wear, oil-film instability, coupling stress, and reduced reliability.

Recommendations

|

Adjust operating points to avoid prolonged operation in 3487-3712 RPM range |

|

Investigate damping enhancements (e.g. squeeze-film dampers) |

|

Verify shaft alignment and balance |

|

Explore structural modifications to shift the natural frequency |

|

Continue vibration monitoring with alarm limits for horizontal vibration |