Case Study: Resonance In Piping Support Structures

Thank you to our friends at JetTech Mechanical for providing this case study

Use this link to download the printer-friendly pdf version: Case Study: Resonance In Piping Support Structures

Introduction

Large commercial chillers are critical to facility operation, supplying thousands of tons of cooling through extensive piping networks. While the machines themselves are designed for reliability, the surrounding support structures may be more vulnerable.

JetTech Mechanical was commissioned to perform routine vibration analysis at Arizona's State Farm Arena. The arena operates six chillers connected to a common chilled water header.

Hardware

Routine data collection was performed with the following hardware:

TREA330

Premium, miniature triaxial accelerometer, 100 mV/g, ±5% sensitivity tolerance

MH114-3T

Multipurpose magnet with triaxial locating notch, 50 lbs. pull strength

CB117-J4C-006-F3D-SFT

CB117 coiled cable with J4C four-socket mini-MIL connector on the left, F3D three-channel BNC plug connector on the right, and SFT breakaway safety feature connector; 6 ft. length

BETAVIB VibWorks King

Data collector

Analysis

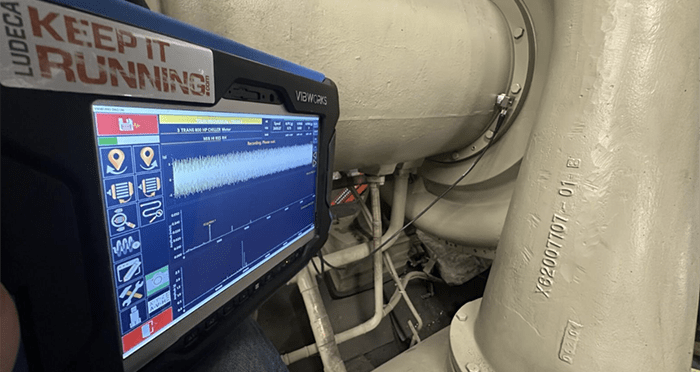

During routine vibration data collection, excessive vibration was detected - not on the chiller, but on the piping support structure. The newest unit, a Trane 862 kW (~1,156 HP) chiller operating at 4160 V and 3570 RPM, was piped into the header alongside the existing chillers. The chilled water lines are supported on H-beam steel mounts. While the supports appeared substantial, vibration monitoring revealed otherwise.

To confirm the root cause, the JetTech team conducted impact testing using the following hardware:

AC192-1D

Compact accelerometer, 100 mV/g, ±10% sensitivity tolerance

MH114-3A

Multipurpose mounting magnet, 50 lbs. pull strength

CB103-K2C-010-F-SF

CB103 two-conductor cable with K2C two-socket MIL-style connector on the left, F BNC molded plug connector on right, and SF breakaway safety feature; 10 ft. length

BETAVIB VibWorks King

Data collector

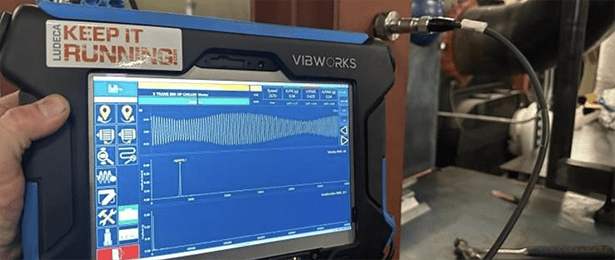

The impact testing confirmed the cause: structural resonance. The results showed that the H-beam supports had a natural frequency of ~59 - 60 Hz, nearly identical to the chiller motor's operating speed of 3570 RPM (59.5 Hz).

When the chiller was online, vibration at the top of the support frame reached about 0.7 in/sec peak at 1x running speed. Amplitudes increase from bottom to top, showing that the structure was resonating in its first bending mode.

Conclusion

It was determined that resonance was exciting the piping support structure at the chiller's operating speed. While the chiller itself was unaffected, the facility faced significant structural risk if left unattended.

Potential long-term effects included:

- Piping chafing against mounts, wearing through insulation and pipe walls

- Fatigue cracks in welds and anchors

- Loosened hangers and piping supports

- Risk of holes in chilled water piping leading to catastrophic flooding

- Leaks at flanges and nozzle connections

JetTech Mechanical recommended the following as corrective measures:

- Stiffening the support frame with gussets, cross-bracing, or tie-backs to raise the natural frequency above ~75 Hz

- Adding damping using constrained-layer materials or viscoelastic pads

- Installing a tuned mass damper (TMD) near the frame, tuned to ~60 Hz

- Isolating piping with spring hangers or isolators (within nozzle load limits)

- Reducing excitation through balance / alignment checks